- Home

- Hair Dryer

- From Factory to Shelf: The Journey of Custom Hair Dryers

From Factory to Shelf: The Journey of Custom Hair Dryers

In today’s highly competitive beauty market, hair dryers have become essential tools in households and salons worldwide. But how do these custom hair dryers make their way from an idea on paper to the shelf of your favorite store? In this comprehensive guide, we’ll explore each step of the journey—from the initial concept, through manufacturing, to the shelves where customers make their purchases.

1. Concept and Design Development

The journey of any custom hair dryer begins with an idea. The design process involves several key steps, focusing on both functionality and aesthetic appeal.

1.1 Market Research and Consumer Insights

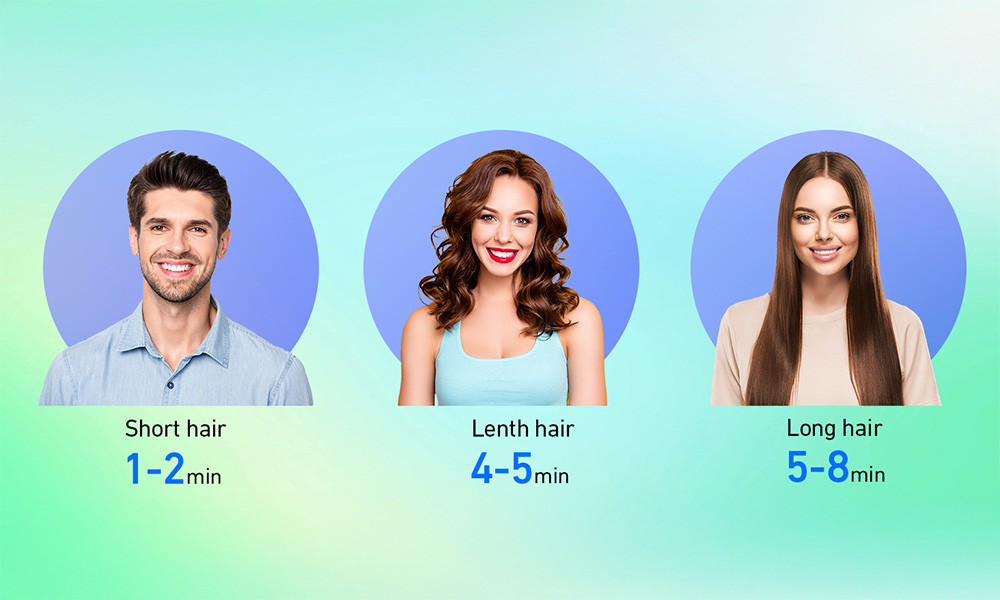

The first step in creating a custom hair dryer is understanding the market. Research teams study current trends, consumer needs, and technological advancements. They look into what customers value most—whether it’s advanced ionic technology, high-speed motors, or lightweight design. Insights from surveys, focus groups, and online feedback help shape the development of new products.

1.2 Initial Sketches and Prototyping

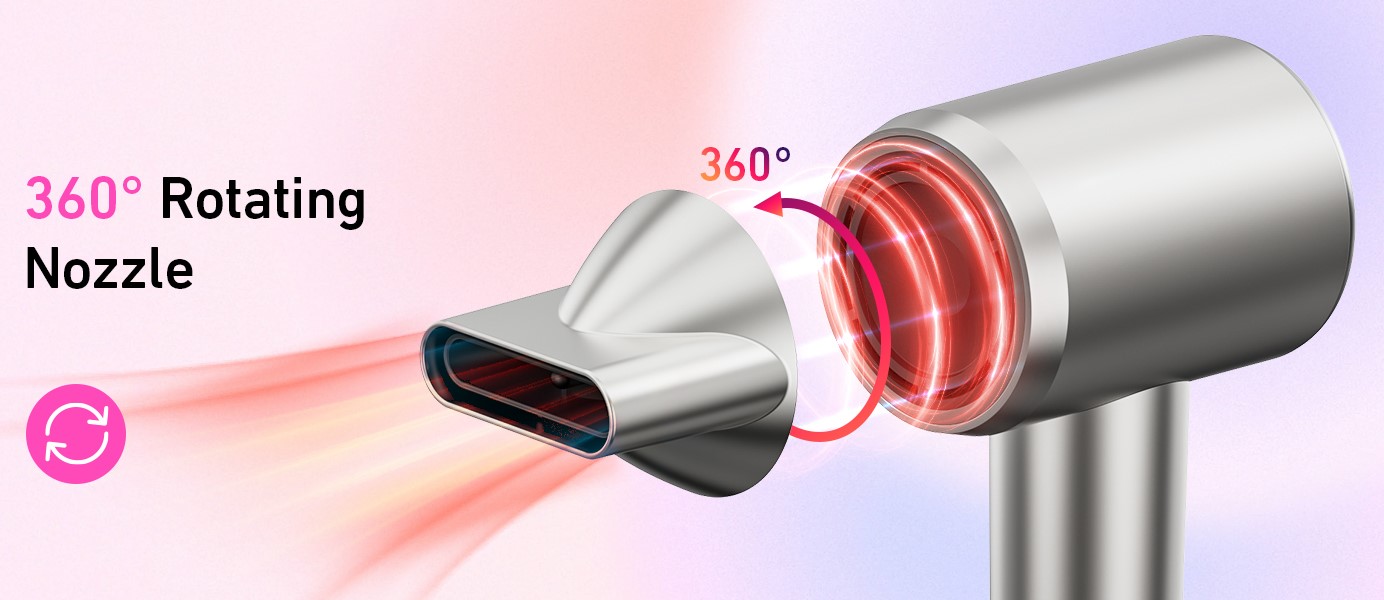

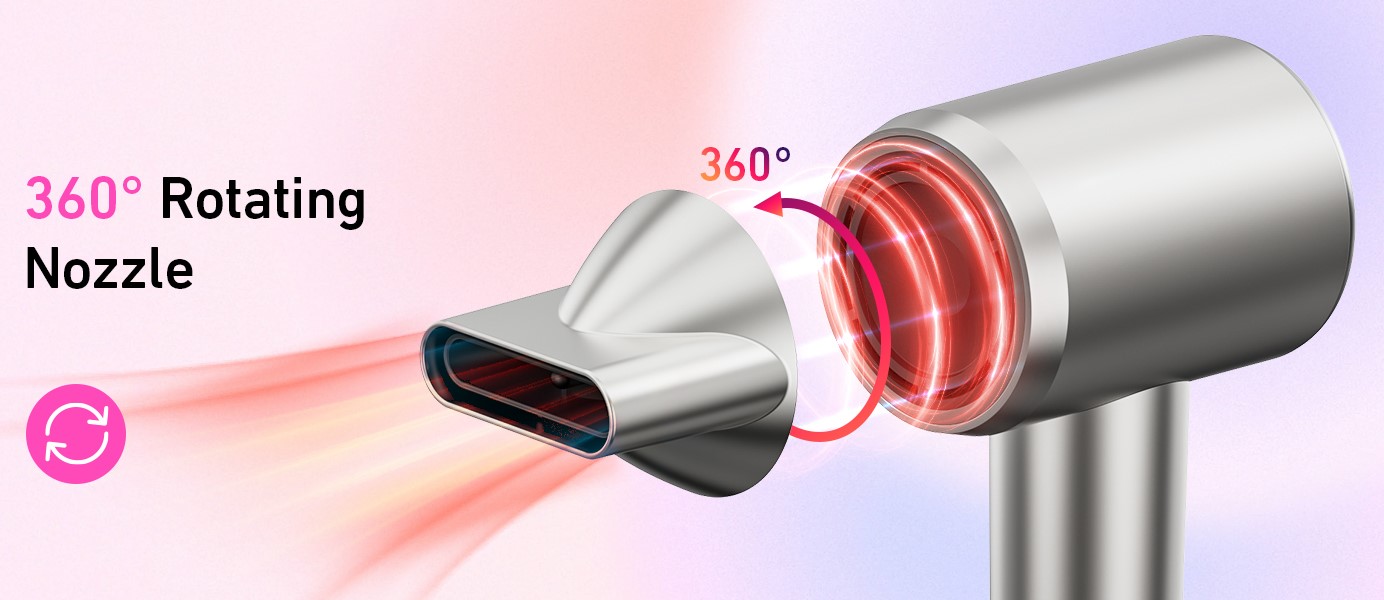

Once consumer needs are identified, designers begin sketching potential hair dryer models. Advanced 3D modeling software is used to create virtual prototypes, allowing designers to visualize the product from every angle. This phase also involves brainstorming features such as heat settings, motor speed, and attachments like diffusers or concentrators.

1.3 Engineering Specifications

Every excellent design has complex engineering at its core. The engine, heating element, fan, and housing of a hair dryer must all function flawlessly together. Engineers design the product’s blueprints to guarantee its efficiency, safety, and durability. To guarantee performance, high-speed brushless motors—such as the one used in the Maxodo High-Speed Hair Dryer—frequently undergo extensive testing.

2. Sourcing Raw Materials

Once the design is finalized, the next step is sourcing the necessary materials to create the hair dryer.

2.1 Identifying Key Materials

The primary materials for hair dryers include durable plastic for the outer casing, metal components for the heating element, and copper or aluminum wiring for electrical conductivity. High-end models may also use ceramic or tourmaline for their internal components to improve heat distribution.

2.2 Partnering with Reliable Suppliers

Manufacturers work with suppliers to source high-quality materials. This phase is critical for maintaining product consistency and performance. Custom hair dryers often require specialized parts, which means manufacturers must establish close relationships with suppliers who can meet exact specifications.

2.3 Quality Control of Materials

Before the manufacturing process begins, raw materials undergo quality control checks. This step ensures that all parts meet safety standards and are free from defects that could affect the performance of the hair dryer. Materials that fail quality checks are either returned to suppliers or discarded to maintain the integrity of the final product.

3. Manufacturing Process

After sourcing raw materials, the manufacturing process begins, transforming design concepts into physical products.

3.1 Assembly of Internal Components

The internal components of the hair dryer, such as the motor, heating coils, and fan, are assembled in highly controlled environments. Automation and skilled workers ensure precision in the assembly process. Advanced custom hair dryers, like those equipped with intelligent heat control, have sensors that must be perfectly aligned for accurate temperature regulation.

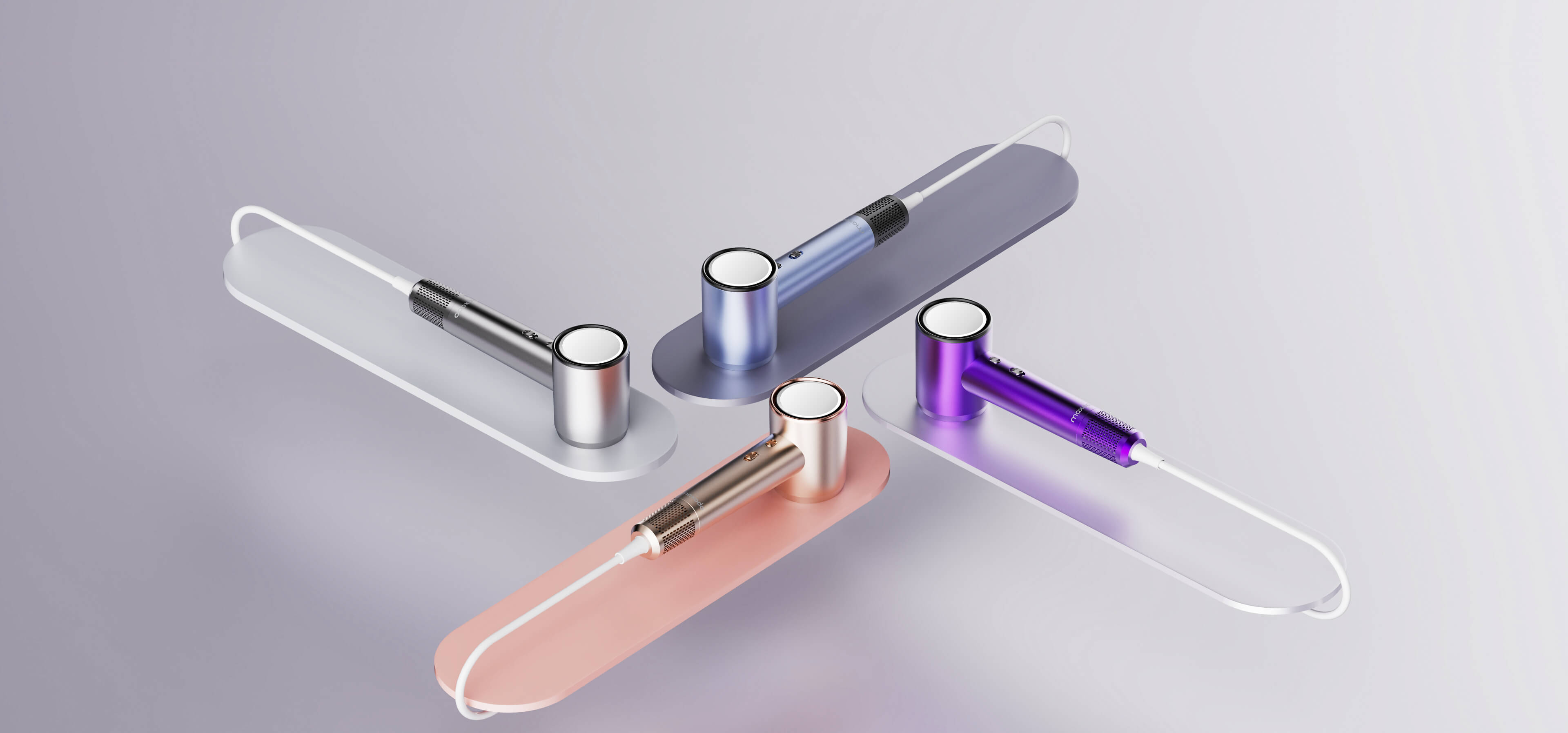

3.2 Injection Molding for Outer Casing

To create the hair dryer’s outer casing, manufacturers use an injection molding process. Heated plastic is injected into molds to form the desired shape of the hair dryer. These casings are designed to be lightweight yet durable enough to withstand daily use. Custom models often include personalized colors and finishes, which are added during this phase.

3.3 Integration of Electronics and Wiring

Once the internal and external components are ready, technicians integrate the electronic parts, including switches, wiring, and circuit boards. Each part is carefully tested to ensure it meets safety standards. The use of high-speed motors, like in professional models, requires precise wiring to ensure the motor operates efficiently without overheating.

3.4 Safety Testing and Certifications

Before hair dryers leave the factory, they must undergo rigorous safety testing. This includes tests for electrical safety, heat regulation, and durability. Many regions require specific certifications (such as UL or CE markings) to ensure the product meets local safety standards. Only after passing these tests are the hair dryers deemed ready for market distribution.

4. Customization and Personalization

Custom hair dryers often go through an additional phase of personalization. This can include branding, color choices, and additional features tailored to specific customer preferences.

4.1 Custom Branding and Logos

For businesses or salons ordering custom hair dryers, branding plays a significant role. Manufacturers often offer options to engrave logos, choose custom colors, or even alter design elements to reflect a company’s identity. This customization makes the product unique and aligns with the company’s brand vision.

4.2 Personalized Features

Customers may request specific features such as extended heat settings, unique attachments, or quieter motors. For instance, the Maxodo Hair Dryer features advanced ionic technology that can be fine-tuned according to the customer’s needs, releasing up to 200 million negative ions to reduce frizz and enhance shine.

4.3 Packaging and Presentation

Custom packaging is another way manufacturers personalize hair dryers. Premium packaging can elevate the customer’s unboxing experience, reflecting the quality of the product inside. Whether the dryer is destined for retail or direct sale to salons, packaging is an essential part of the branding strategy.

5. Distribution Channels

Once the hair dryers are produced and customized, the next phase involves getting them to customers.

5.1 Direct to Retailers

Many hair dryer manufacturers work directly with retailers, including online platforms like Amazon, beauty supply stores, and department stores. Retailers often negotiate bulk pricing, ensuring they can meet consumer demand. High-end models like those with professional-grade motors and advanced heat controls are frequently sold in specialty beauty stores.

5.2 Direct-to-Consumer (DTC)

With the rise of e-commerce, many companies have shifted to a direct-to-consumer (DTC) model, selling hair dryers via their websites. This model allows manufacturers to control branding, pricing, and customer relationships more effectively. Platforms like Shopify and WooCommerce have enabled businesses to set up online stores with ease, making it simpler for consumers to buy directly from the manufacturer.

5.3 Wholesale and B2B Sales

For salons and professional stylists, hair dryer manufacturers often sell in bulk through wholesale channels. This B2B model allows professional users to access discounted prices and custom features that cater to the high demands of daily salon use. For example, hair dryers designed for salons may have heavier-duty components to withstand long hours of continuous use.

6. Marketing and Promotion

Marketing plays a crucial role in the success of custom hair dryers. Here’s how companies promote their products.

6.1 Digital Marketing Strategies

Social media, influencer partnerships, and search engine optimization (SEO) are key strategies for promoting hair dryers. Instagram and YouTube are popular platforms where beauty influencers showcase the latest models. At the same time, optimized product descriptions and blog articles, like “How to Choose the Perfect Hair Dryer,” help brands rank higher on search engines, increasing visibility.

6.2 Partnerships with Salons and Stylists

Manufacturers often form partnerships with professional salons and stylists to promote their products. Salons may feature custom hair dryers in their services, and stylists provide testimonials that add credibility to the brand. These endorsements are invaluable for boosting sales, especially for high-end, professional-grade dryers.

6.3 Trade Shows and Beauty Expos

Another key avenue for promotion is attending trade shows and beauty expos. These events allow manufacturers to showcase their products to industry professionals and buyers. Custom hair dryers often stand out at these events due to their unique features and designs, helping companies establish industry presence.

7. Post-Purchase Support and Service

Customer satisfaction doesn’t end at the point of sale. Post-purchase support is critical for maintaining brand loyalty and ensuring long-term use of custom hair dryers.

7.1 Warranty and Maintenance Services

Most manufacturers offer warranties that cover defects in materials and workmanship. For professional hair dryers, extended warranties are often available to cater to the heavy use in salons. Maintenance services, such as motor replacement and cleaning, are also essential for prolonging the life of the product.

7.2 Customer Education and Tutorials

Customers who purchase high-end or custom hair dryers often need guidance on using the product correctly. Many manufacturers provide tutorials, both in printed form and online, to help customers make the most of their purchase. Video guides, in particular, have become a popular way to demonstrate how to use various attachments or adjust heat settings for different hair types.

7.3 Feedback and Product Improvements

Lastly, customer feedback is critical for ongoing product improvements. Manufacturers regularly collect feedback from users to identify any issues or features that need enhancement. This continuous improvement loop helps companies stay competitive and innovate in the crowded hair dryer market.

8. The Future of Custom Hair Dryers

The future of custom hair dryers is bright, with innovation driving new developments in both design and technology.

8.1 Smart Technology Integration

Hair dryers are becoming smarter, with the integration of digital displays, intelligent heat control, and even Bluetooth connectivity. These advancements allow users to customize their experience further, providing more control over temperature, speed, and ionic output.

8.2 Sustainability and Eco-Friendly Materials

As consumers become more environmentally conscious, manufacturers are exploring sustainable materials and energy-efficient motors. The use of recycled plastics and low-energy heating elements is becoming more common, helping reduce the carbon footprint of hair dryer production.

8.3 Augmented Reality in Customization

In the future, customers may be able to design their own hair dryers using augmented reality (AR) tools. These tools would allow users to visualize how different colors, finishes, and features would look before placing a custom order.

Conclusion

The journey of a custom hair dryer from the factory to the shelf is a complex but fascinating process. Each step, from design and manufacturing to marketing and distribution, plays a crucial role in ensuring the final product meets customer expectations. As technology advances, the world of custom hair dryers will continue to evolve, offering even more options and innovations for consumers and professionals alike.

Popular Post

Ultimate Guide to Using a Hair Dryer with Nozzle for Styling

The Benefits of Using a Hair Dryer with a Diffuser